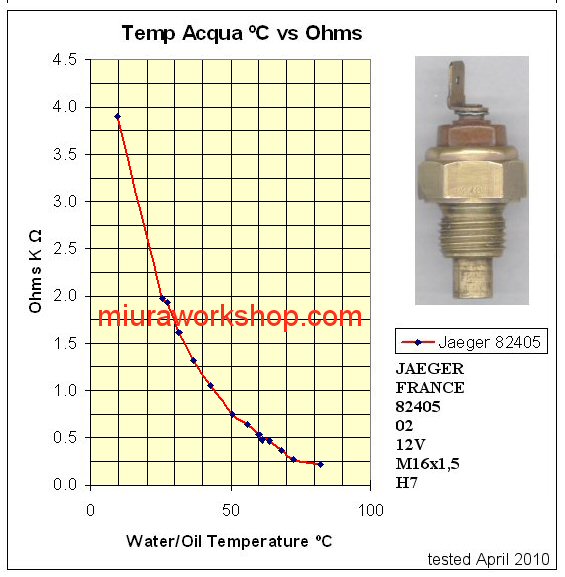

As a quick check of a known accurate sender, the study to the right was produced in April of 2010. The sender was not heated to the end point of 130C as we only had limited shop hot water.....we achieved a steady 82C.

There was an observed reaction time of the sender to temperature increase and it was found to about 30-40 seconds for the 10 deg C increase range we tested.

Tip from Jeff north - A quick check is to attach the sensor wire to the other Jaeger sensor, which is the same unit, and read the gauge. If the gage works, replace the sensor in question.