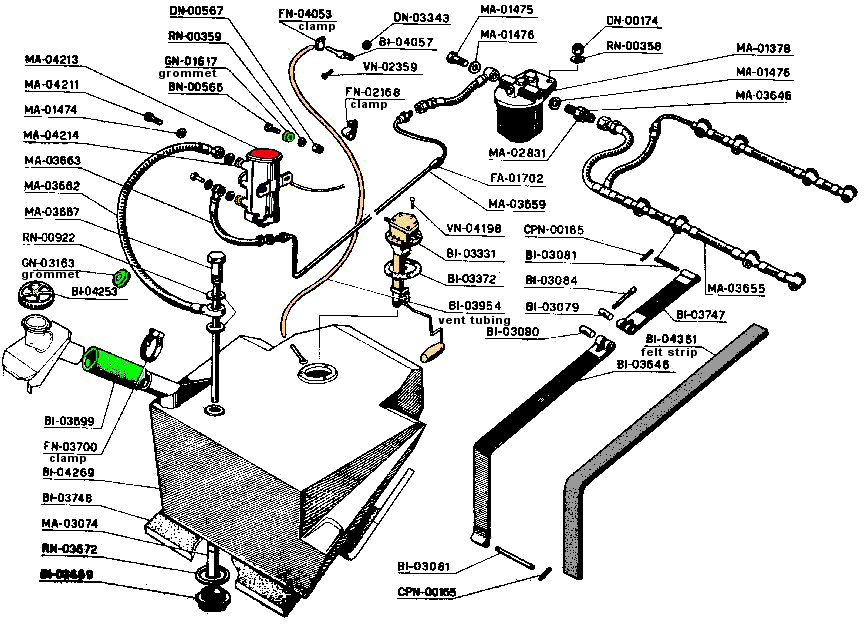

part number

details

tappo serbatoio benzina

bouchon reservoir

8830111

not shown

8700405

8401804

8404001

6205360

Model A Ford float can be a direct replacement for Lamborghini Jaeger float

| Description |

Lamborghini part number |

OEM details |

Notes |

note 2 |

|

| pump, electric, Bendix |

MA-04213 |

Bendix, Elmira, #480532,

neg.12v |

red top |

small sediment filter in

base cap |

|

| cap, gas tank fill |

BI-04253 |

gas tank cap tappo serbatoio benzina bouchon reservoir |

black plastic |

used on Lambo

350/400, Ferrari 275/330, and ? |

|

| pin, strap - 2ea |

BI-03081 |

6 x 60 steel pin, 2mm

holes on 56mm center |

black |

||

| pin, cotter - 2ea |

CPN-00155 |

2mm cotter pins |

plain |

||

| screw, draw |

BI-03084 |

5 x 0.8 , slotted,

cylinder head special |

black |

||

| pin, strap draw |

BI-03079 |

12 x 30mm, 6mm hole,

2.5deep x 10across recess flat, steel |

black |

||

| pin, strap draw |

BI-03080 |

12 x 30mm, threaded 5 x

0.8 , steel |

black |

||

| strap, gas tank short |

BI-03747 |

1 x 30 steel material,

110mm center eye to eye, 12mm width slot thru large eye, spot welded

end loops |

black paint |

||

| strap, gas tank long |

BI-03646 |

1 x 30 steel material,

605mm center eye to eye, 90 bend @118mm from large eye center, 12 mm

slot, spot |

black paint |

||

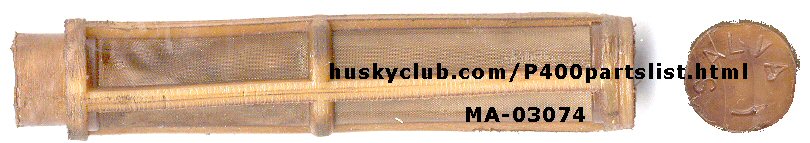

| filter, pick up |

MA-03074 |

SALVA, 10mm ID x 15.3 OD x 80mm overall length |

nylon mesh |

see photo |

|

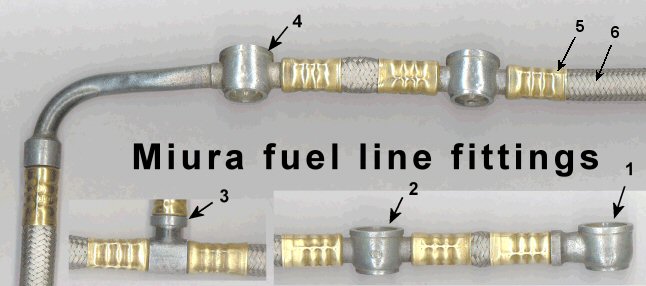

| fuel pick up pipe |

MA-03667 |

banjo fitting with brass pipe brazed in |

non-magnetic |

see photo |

|

| gasket, copper washer |

RN-00922 |

18.05mm ID x 30mm OD x 1mm thick |

copper |

||

| vent fitting |

BI-04057 |

aluminum fabrication, simple straight thru vent |

unpainted |

|

|

| tubing, vent |

BI-03954 |

green, Cavis, 6mm, plastic tubing |

green plastic |

||

| screw, machine oval |

VN-02359 |

4.0mm x 0.70 x 10mm, oval head, straight slot, brass, chrome |

chrome |

||

| screw, machine round |

VN-04198 |

4.0mm x 0.70 x 30mm, round head, straight slot, steel |

clear zinc |

||

| nut |

DN-03343 |

4.0 x 0.75, brass |

brass |

||

| clamp, band - 2ea |

FN-02168 8830111 |

steel, simple P loop, 10mm wide, 6mm hole, loop to fit OD of green Cavis vent tubing |

black |

||

| screw, sheet metal, not shown |

VN-02847 8700405 |

to fasten FN-02168, Panhead, Phillips, sheetmetal screw 4.8 x 9.5 Din 7981 / N |

clear zinc |

||

| gasket, red fiber |

MA-01474 |

14 x 10 x 2 red fiber gasket ring | |||

| gasket, red fiber |

MA-01476 |

20 x 14 x 2 red fiber gasket ring |

|||

| gasket, copper |

RN-00922 8401804 |

annealed copper washer 18.2 x 30 x 1 |

copper |

||

| gasket, copper |

RN-03672 8404001 |

copper washer 40.2 x 54 x 1.5 | copper |

||

| gasket, paper |

BI-03372 6205360 |

fuel level sender gasket paper or elastomer |

black neoprene |

||

| sending unit, Jaeger |

BI-03331 |

clear zinc |

|||

| float, sending unit |

OEM cork float dimension - 28mm dia x 42mm long x 2mm bore Model A Ford float can be a direct replacement for Lamborghini Jaeger float |

cork or better |

http://www.mikes- |

||

| Bendix / Facet number |

Rating |

size |

automotive known as |

notes | source for purchase 2007 |

aprox price |

| 480532 12V neg |

45gph/5.0psi | 1/4 npt |

competition red top |

early Bendix pump - entire pump dome

is painted red, the later Facet pump - red dot sticker pasted on. The OEM Bendix is silver Zinc plated, while the later Facet has been chromated to a gold color. Also a change in the electrical fitting. | Truechoice Motorsports 40 Industrial Park Place Powell, OH 43065 www.truchoice.com |

$93 |

| |

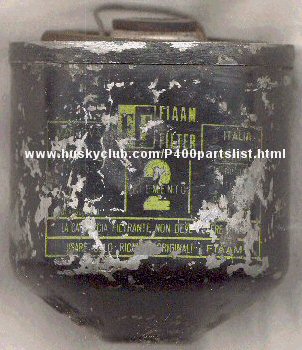

top view Fiamm fuel filter  |

|

|

Fiaam fuel

filter hardware red paper gaskets clear zinc plated hardware |

|

Bendix

"Elmira" Photo shows an unrestored 1968 Bendix from a 1968 Miura One of the amatuer restoration mistakes is the placement of the Bendix sticker. While the sticker would look nicer on the forward side, it is only correct on the rear side as shown. There are three different Miura mount styles for this Bendix electric fuel pump. Early Miura style, late Miura style, wrong Miura style. |

|

|