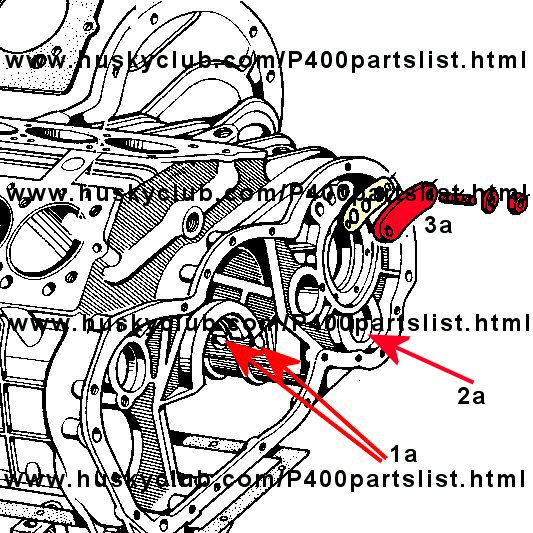

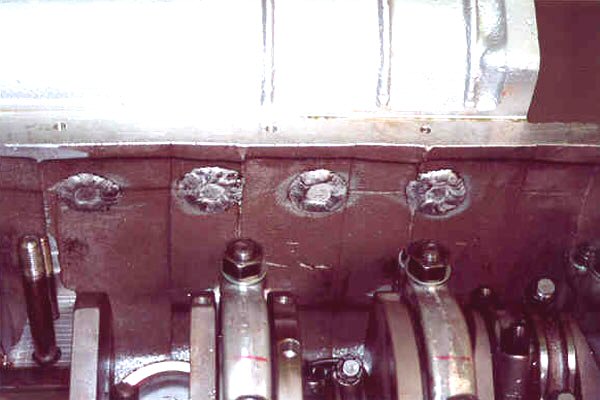

-fabricate cutom plug.

-modify engine block to accept new seal plug.

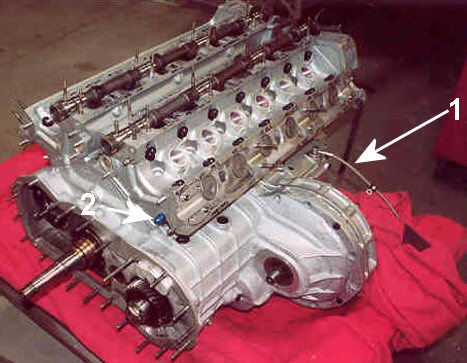

2b) sealing the upper transmission shaft

-drive gear modification to accept lip seal.

-plate modification to accept lip seal assembly.

-seal adapter plate fabricated and installed.

-appropriate lip seal.

2c) left hand thread end lock requires seal modification.

4a) venting the transmission / differential

4a) venting the transmission / differential 5) split sump transmission oil level

5) split sump transmission oil level